Vantage Technologies USA

Harnessing the power of plastics to be your low cost thermoforming solution

Compression Molding

From a twelve-inch panel to a twelve-foot headliner, our innovative process is flexible to meet any design.

Vacuum Forming

An economical and versatile method for bringing your parts to life. Quick turnaround, low cost, and rapid engineering changes are just a few advantages we can bring to your project using this forming method.

Prototyping

Vantage is your best option when it comes to prototyping. Our unique processes permit low cost tooling and enable us to quickly get your samples and prototypes into your hands. Contact us to request a quote and see for yourself!

Rapid Tooling

Our methods allow for the manufacture of production-ready epoxy tooling, thus lowering cost and shortening your time to market while maintaining the quality you expect from steel or aluminum tooling.

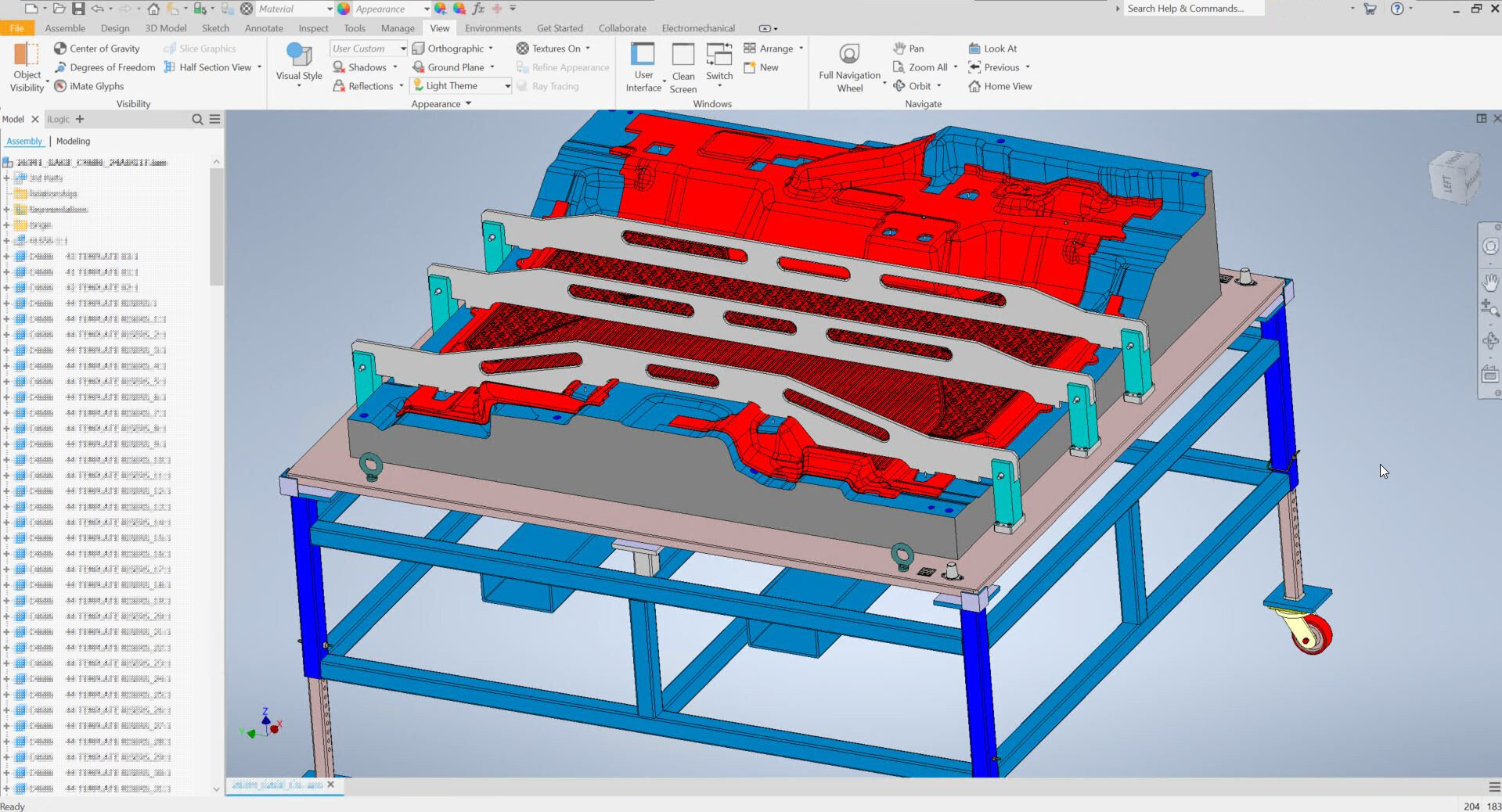

Design

We use the latest CAD software to design, modify, and review your parts and tools. Send us your data or concepts and watch your imagination become reality!

Low Volume Production

Whether you need 5, 50, or 5000 parts made, Vantage will work with you to be your one-stop resource for all your low volume production needs.

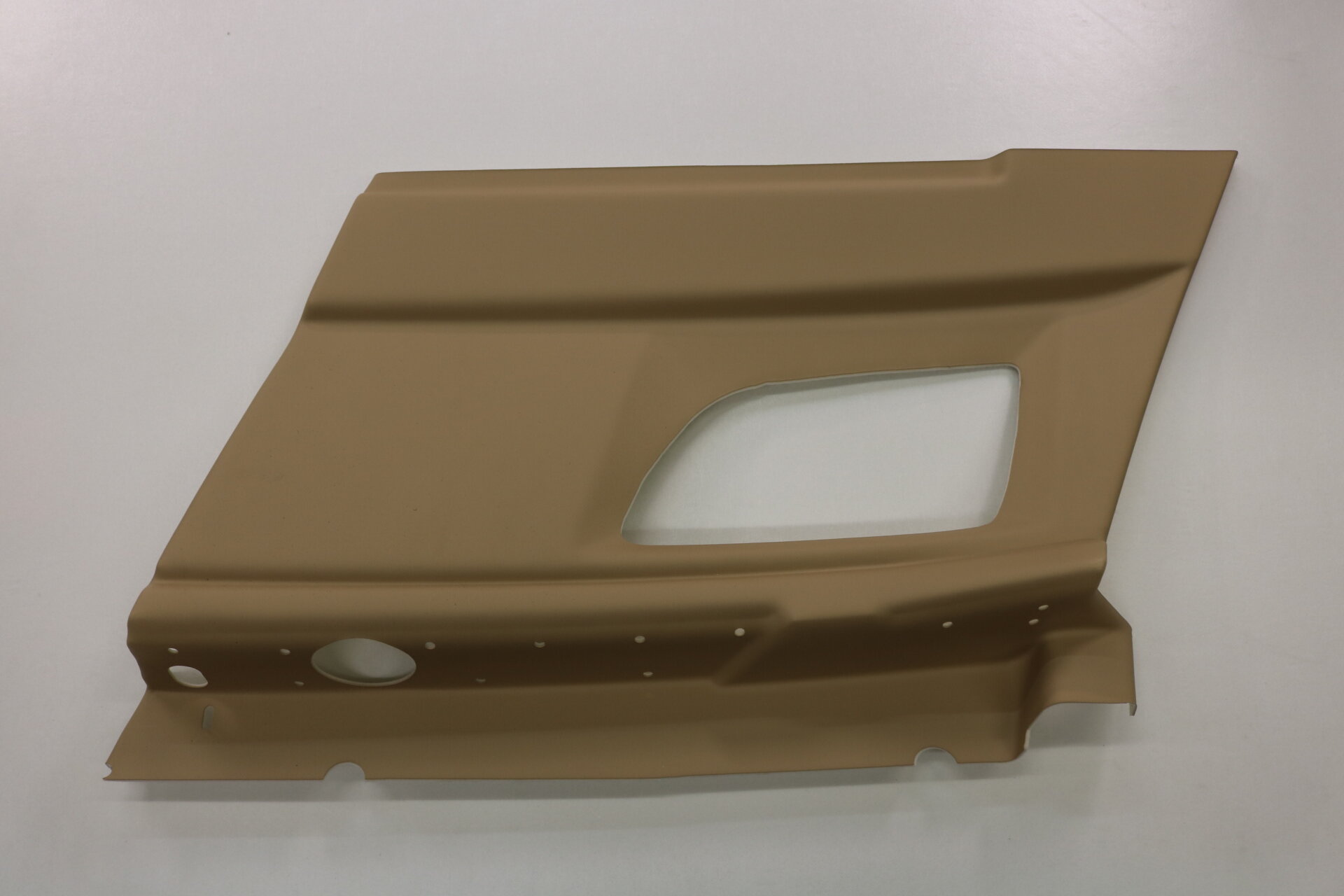

Interiors

Our thermoforming capabilities include both compression and vac-form molding to complete your custom interior. No design concept is out of reach when Vantage can meet your every need.

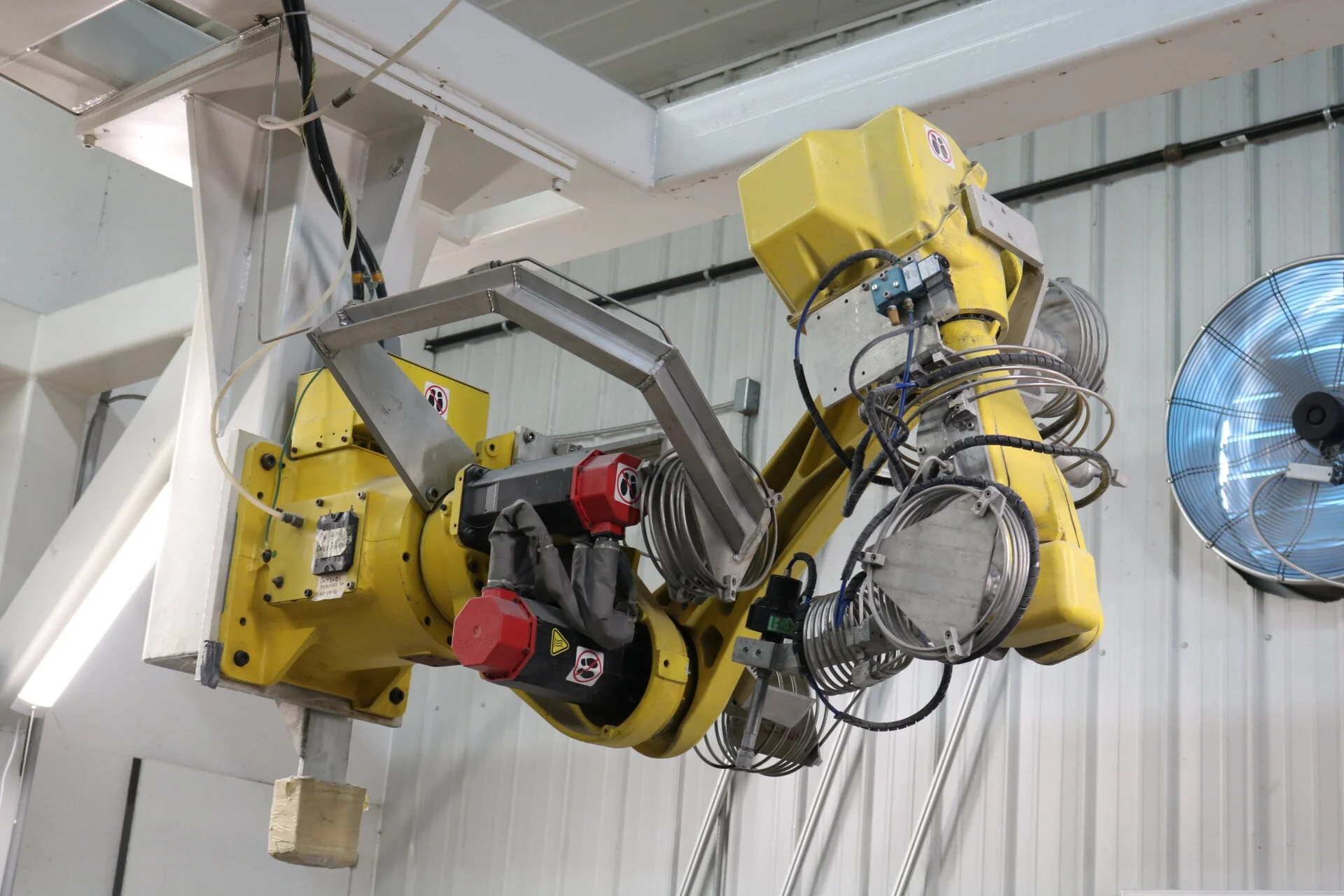

Water Jet Trimming

Using extremely high pressure water and robotic path programming, we can quickly and accurately trim your parts to the tightest tolerances.